Storage Tank Emissions Assessment and Quantification (STEAQ)

Summary:

The proposed project will characterize emissions from storage tank batteries (system consisting of produced water, natural gas, and storage tanks) to improve the accuracy and completeness of emissions reported in inventories. Since the focus of this funding opportunity announcement (FOA) is on methane emissions, the proposed scope of work consisting of field measurements and improved emissions factors will also focus on the upstream and midstream sector, where natural gas is in contact with liquids in tanks, producing significant amounts of methane emissions. Tanks in the oil supply chain, while they may have significant gaseous emissions, typically have much lower methane content. The causes of tank emissions are discussed in Merit Review Criterion 1 (MRC 1).

To characterize tanks, the project team recognizes that tank emissions have two vastly different causes: (a) ongoing emissions from gas flashing from liquids in the tanks, and (b) the process or operational problems that create exceptional emissions when gas from other processes enters into and emitted from these tanks. Therefore, any effective characterization of tanks must understand ongoing emissions and characterize intermittent events.

Operators are also developing smarter, more integrated facilities. New monitoring and control technologies are being rapidly implemented on production facilities. For example, many facilities are equipped with tank pressure monitors and these can sense over- or under-pressure conditions, alarm operators, or shut in a facility. Operators are also implementing tank gas recovery systems which replace flares, which change the nature of both failure modes and emission mechanisms. Thus, our proposed project will attempt to characterize the performance of these advanced systems and develop guidance on their effectiveness.

Objectives:

Our objectives in STEAQ are to:

- Develop an accurate database on storage tank configurations and the associated equipment through operator surveys including but not limited to tank type, function, age, gas throughput, etc.

- Develop emission factors for tanks that are sensitive to differences between basins, production types, age of facilities, and other variables.

- Understand the causes, frequencies, and rates of intermittent emitters, and represent those results in emission factors or emission estimation methods.

- Develop guidance on the effectiveness of tank monitoring and control systems for detecting and mitigating emissions.

Project Plan:

To accomplish these objectives, the proposed project will implement two field elements, simultaneously:

1. A traditional field campaign, as described above, will collect operational data and measure emissions storage tank batteries on an estimated 750 facilities nationwide. The field campaign will collaborate with operators for facility access and to identify causes of emissions. The same team in this field campaign will conduct the following three tasks:

a. Operator Survey (Objective #1): The operator survey will gather data on storage tank battery configurations and associated equipment for selected basins or regions to meet the first objective of the proposal. Such data may include equipment count, type, function, age, throughput, composition, maintenance data, truck loading, seasonal variations, etc.

b. Emission Measurement (Objective #2): A carefully designed field campaign will measure emissions from representative sample of tanks using common field methods, such as OGI + Hi-Flow. Teams will visit facilities to measure tanks ‘as found’ and collect data on the cause of any exceptional emissions, if occurring. Partner companies will provide escorts for, or assistance with, this sampling.

c. Collect Samples (Objective #2): The field campaign will include collection of gas and liquid samples to assist emission characterization to inform first-order analysis of failure conditions to better understand the process origin of emitted gas.

2. A separate field effort will use non-invasive monitoring methods, primarily next-generation imaging methods, to monitor tanks for extended periods (1-3 months for a single tank battery) (Objective #3). Monitoring will identify the occurrence of, and estimate the rate of, intermittent emissions. To accomplish this monitoring, we will use well-developed stationary camera systems and develop novel monitoring methods. Such methods will quickly relocate systems from facility to facility to provide broad coverage of facility characteristics.

Basins will be selected in conjunction with operator partners to provide representative sampling of facility types in upstream and midstream, different basin characteristics for upstream (e.g., gas-oil ratio), monitoring and control systems, and other factors, such as facility age and design. The exact mix of facilities will be defined during field campaign planning.

The ultimate goal of this work is to not only report emissions more accurately but also mitigate emissions. Objective #4 is the guidance on the effectiveness of storage tank battery monitoring and control systems and is the most actionable for operators, as well as having the most direct path to mitigation. It must therefore be infused into both field elements. By including monitored and unmonitored facilities in the study, and if sufficient sample size can be isolated, the project will also provide guidance on the effectiveness of monitoring and control methods.

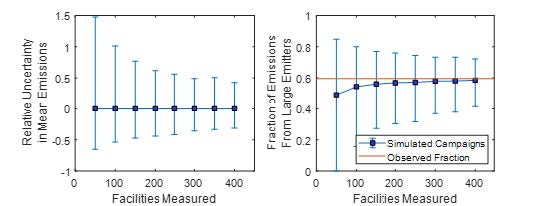

To estimate the size of the required field campaign, a statistical power simulation was conducted using tank emissions data from a recent study3. The study found 130 emitters on 251 measured tanks, of which 6 emitters (4.6% of sources) were classified as “large emitters” that could not be measured using handheld high flow equipment. Modeling of the large emitters estimated that 60% of emissions were due to these sources. Using tank counts per facility from well pads in the Denver Julesburg Basin of Colorado (4.5 [1 to 20], 95% confidence interval), per-category field campaigns were simulated for sample sizes of 50 to 400 facilities, the results of which are shown in Figure 1.

Figure 1: Statistical power simulation for the field campaign

The simulation is informative:

• Assuming the long tail in emissions, 4.6% of sources constituting 60% of emissions is representative of tanks nationally. Any size of field campaign is unlikely to produce uncertainty in mean emissions of less than +50/-30%;

Campaigns larger than 250 facilities per tank or of a various operational type will approach the point of diminishing returns, as uncertainty does not reduce significantly for larger campaigns, relative to resources required;

• Campaigns of at least 200 facilities per tank or operational type are required to capture the impact of large emitters (left panel in the below figure); and

• Large emitters must be identified and measured during the field campaign.

Therefore, we propose a field campaign of approximately 750 facilities, which should be sufficient to sample 3-5 categories of tank or operational types within a sufficient sample size. This sample size ought to be sufficient to analyze by major categories by tank contents, by tank control systems, by supply chain sector, or by production type of gas, oil, associated gas, midstream, etc.

The above analysis simulated a standard field campaign using a traveling measurement team. To improve coverage, and to also identify intermittent emitters, the project also plans to deploy approximately 15 stationary cameras that can be moved between facilities to detect and estimate emission rates at facilities. While we expect wide uncertainty in emission rate estimates from the cameras, each camera provides the equivalent of 15 site-visits per month to each monitored facility. By moving each camera every 1-3 months to a new facility, and allowing for transport and maintenance time, we expect to observe 150-300 tank batteries for a month or more during the project.

In summary, the technical approach contains the following elements:

- A traveling field team to visit about 750 facilities over the course of the project, making as-found or snapshot measurements.

- The same field team will also record operational survey data about storage tank battery configurations and associated equipment.

- Collection of gas and liquid samples to improve measurements and inform causes of emissions.

- Sampling of large emitters by the field team or an accompanying team using alternative methods, during the field campaign in.

- A separate field measurement with extended duration monitoring to identify large emitters, emitter frequency, and intermittent emissions.

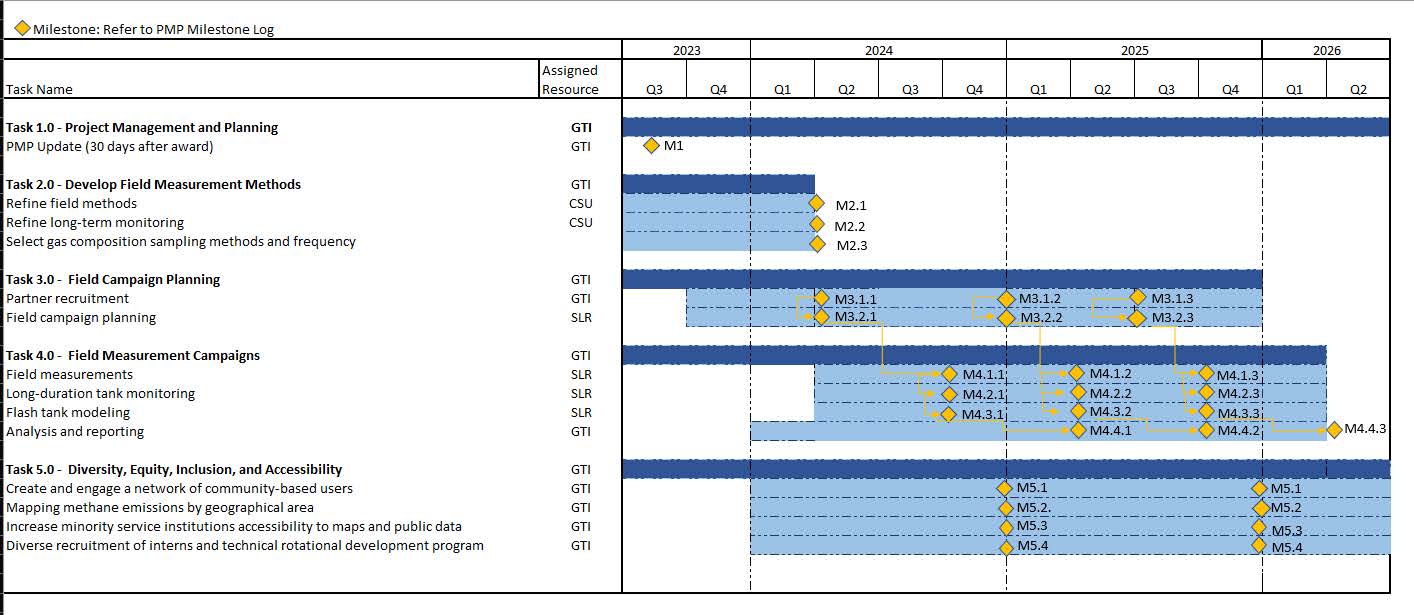

- The project is formulated in five tasks, with tasks 3 and 4 repeating 3-4 times to complete field park in several tranches:

Task 1. Project management: As required by the FOA.

Task 2. Method development: Prior to the field campaign tranche in tasks 3 and 4, the proposal team will develop field measurement methods as outlined in Section 2.0.

Task 3. Field campaign planning: The proposal team will recruit partners, define basins and sectors to be measured, and plan the field campaign.

Go/no-go: The proposal team will present the next tranche of the planned field campaign to the DOE for go/no-go decision to proceed with the field campaign.

Task 4. Field campaign: Execute the field campaign, QA/QC data, summarize, and report.

Task 5. Diversity, Equity, Inclusion, and Accessibility: Execute the DEIA plan.

Tasks 3 and 4 will repeat 3-4 times, with the indicated go/no-go decision between planning and execution, incrementally covering basins nationally in both upstream and midstream natural gas supply chain sectors. The proposed go/no-go decision points provide the DOE positive control over the commitment of funds to the project.

CSU will lead methods development and partner on field campaign planning, based upon prior work on field campaigns. Imaging solutions will be evaluated at METEC to assess accuracy, weather lock-out conditions, and deployment requirements. CSU will also deploy a mobile measurement capability to a subset of field sites to measure large emitters, and to do in-situ tests of the imagers.

Figure 2: Examples of imaging systems monitoring upstream equipment.

Schedule:

Results:

TBD

Opportunities to Participate:

Interested in participating?

- Contact [email protected] for further information.

Funding Provided by:

GTI

DOE FECM

Collaborators:

SLR