Methane Emissions Technology Evaluation Center (METEC)

The U.S. Department of Energy’s Primary Methane Emissions Technology Research Facility

The Methane Emissions Technology Evaluation Center (referred to as METEC) is a unique and renowned test and research facility for emissions leak detection and quantification (LDAQ) technology development, field demonstration, hands-on LDAQ equipment training, and protocol and best practices development. The METEC facility is operated by the Energy Institute at Colorado State University (CSU) and is located on CSU’s foothills campus.

The five-year METEC 2.0 project funded by the Department of Energy, will extend the life and capability of DOE-funded assets that have been developed at the METEC facility since 2016 to speed deployment of next-generation leak detection and quantification technology solutions. A SOURCE article on the CSU website provides additional details.

What is METEC 2.0?

METEC 2.0 is a multi-pronged effort to improve the characterization of leak detection and quantification (LDAQ) solutions. Well-characterized solutions are critical for oil and gas (O&G) operators to use LDAQ solutions for monitoring their emissions, reporting to voluntary or regulatory programs and to implement effective emissions mitigation programs.

METEC 2.0’s formal name is Capabilities Enhancement for Methane Emissions Technology Evaluation Center (METEC) to Decarbonize Natural Gas Resources.

Key components of METEC 2.0 include:

- Updating the METEC facility to more closely mimic current oil and natural gas facilities. METEC is a primary location for ‘controlled release testing’—releasing gas from equipment in a highly realistic, but completely controlled, environment. A controlled environment allows hundreds of experiments to be conducted a reasonable test program—METEC Testing Programs—something that’s hard to accomplish in field testing.

- Creating mobile controlled release capabilities to support METEC-like testing on other facility types and in other geographic areas. LDAQ solutions need to be tested across a diversity of facility sizes, weather conditions, and facility complexity. An early target for this capability will be midstream—facilities in gas gathering, transmission, and storage.

- Addressing several key LDAQ niches that need special attention such as offshore platform emissions and characterizing facility-scale methane satellites.

- METEC has always performed a dual role of both testing and encouraging LDAQ solution development. This work continues with METEC 2.0 funding for testing programs that use METEC 2.0’s diverse testing capability.

- When testing at any location, METEC 2.0 includes collection of extensive meteorological and gas concentration data to help O&G operators and solution developers improve their technologies.

- Hydrogen-natural gas blends may soon be added to U.S. pipelines. METEC 2.0 includes initial steps to extend METEC’s ability into testing and development for these ‘hyblend’ gas mixes.

METEC will continue to have an active Industry Advisory Board (IAB), open to all entities with an interest in methane emission detection and mitigation. For information about the IAB please contact Kate Laughery (kate.laughery@colostate.edu).

While METEC is focused on methane emissions from oil and gas, methods developed or assisted at METEC will be applicable to other methane sources from agriculture and waste management.

The METEC research group is more than METEC 2.0. We also conduct extensive field campaigns and develop emissions modeling software.

What’s happening with METEC 2.0 right now?

March-May:

- Design and build of the first autonomous mobile methane measurement unit (AMMUs)

-

- The purpose of each AMMMU is to provide a mobile platform for methane and environmental measurement that can be used to generate datasets that will drive machine learning and provide data for validating models. The AMMMUs will be deployed at METEC and then moved to the more aerodynamically complex field sites when available.

- Building Data Sets

- Engaging with offshore partners

-

- We need operator, agency and solution developer input to define our offshore testing capabilities.

- Contact Stuart Riddick (Stuart.Riddick@colostate.edu) to participate in this design process including the prioritization of facility types, locations, and testing characteristics.

- Testing Offshore

- Planning methane satellite testing programs

-

- Design workshops/webinars will be held with satellite developers, operators, and other interested parties. Input is particularly urgent given the pending launch of several new methane satellites during the first two quarters of 2024. Host locations for testing are also of interest.

- Contact Ezra Levin (Ezra.Levin@colostate.edu) to join these discussions.

- Testing Satellites Using Midstream Facilities

- Revision of the widely-used ADED protocols

-

- The ADED Team has begun evaluating and revising the ADED protocols for continuous monitoring and survey solutions. The focus of this process is to evaluate the existing protocols as implemented and identify gaps or operational implementations that now exist.

- Engage: An initial meeting with the Protocol Development Committee in November, started the revision efforts and was followed by an operator’s session at The Environmental Partnership Annual Meeting in December. An in-person session for solution and technology developers to provide their input was held in February 2024. More in-person meetings and virtual sessions will be hosted in 2024.

- For more information: https://metec.colostate.edu/aded/ or contact Ethan Emerson (Ethan.Emerson@colostate.edu)

- Engaging with METEC IAB and other interested partners in the METEC facility revisions

- The METEC facility will be updated to make it more representative of today’s oil and gas facilities, including the selective addition of new equipment and facility elements, improving the realism of testing. METEC staff will develop a strawman of facility modifications and then seek extensive stakeholder feedback to ensure the facility meets testing needs.

- Contact Kate Laughery (Kate.Laughery@colostate.edu) to participate in this design process.

Background Information

METEC Facility

The METEC facility was developed with funding from DOE’s Advanced Research Projects Agency, Energy (ARPA-E) in 2016, with most infrastructure constructed during 2017. Conceptually, METEC has always included both above-ground emissions from oil and gas equipment and under-ground emissions from pipeline leaks.

METEC’s equipment is real—donated by members of the METEC IAB—but is not operational. Gas is delivered to leak locations via small-diameter tubing, and equipment has been modified to ‘leak’ in a convincing fashion. Using our extensive field knowledge, we have engineered the leak locations to look and feel realistic. Emissions occur where they would in the field, with the variability and rates seen in field studies. As currently configured, METEC has approximately 200 above-ground release points, all of which are remotely controlled, from 6 pads and 4 facility types. The site can run many emissions at known flow rates simultaneously to emulate stochastic emissions observed on operational facilities.

Another way to think about METEC is, oddly enough, as a ‘wind simulator.’ The METEC facility mimics real-world oil and gas facility layout and equipment. As a result, wind transport disperses emissions similar to real-world conditions. This allows LDAQ solutions to understand how their solutions operate in challenging field conditions using controllable emissions sources. The result is a unique facility for developing and characterizing LDAQ solutions.

Two pipeline testbeds were developed in 2017–18 as part of the initial facility construction. Underground test beds include an array of underground resources that emulate natural gas pipelines—both pipeline structures and rights-of-ways (ROWs) with hidden leak locations. METEC also has unique engineered test beds for underground emissions research—a 10×20-meter sand-filled pit, 2 meters deep, with specially engineered underground features for disrupting gas flow. This testbed provides a unique, controllable, facility for developing fundamental models of gas migration.

The research team at METEC specializes in developing approaches to evaluate open research questions, providing technical expertise to regulators and oil and gas operators, and advancing technologies to mitigate methane emissions through rigorous test programs. Examples of such work include measuring of 300+ orphaned and abandoned wells in Colorado—the largest single-set of measurements to date on this class wells—evaluation of 30+ technologies through the Advancing the Development of Emissions Detection (ADED) project, training optical gas imaging technicians, and providing guidance on test programs for over 100 companies and technologies.

METEC Testing Programs

Evaluating methane emission detection solutions at METEC can occur in three different testing modes:

- Ad-hoc or ‘white box’ testing provides an opportunity to conduct research and/or develop new and existing leak detection solutions by testing in a more complex environment. While performing ad-hoc testing, a METEC client controls where, when, and how large gas releases are, to support exploratory research or to validate product capabilities. Whether developing innovative technologies, refining algorithms, or rigorously testing solutions, ad-hoc testing is conducted without the constraints of protocol testing.

- Data provisioning allows solution developers to passively test their sensors or solution while other testing is occurring—a test mode often called “piggybacking.” Data provisioning customers have no input over the controlled release planning but receive the controlled release data and site meteorology after testing. Data provisioning allows solution developers to gather large amounts of field experience at reduced cost. It also helps METEC by adding flexibility to the testing calendar.

- Protocol testing is a single-blind test program—tested solutions do not know the location, size or timing of emissions. Currently, all protocol testing at METEC is performed to the ADED consensus protocols for continuous monitors and survey solutions. METEC typically offers one 3-month continuous monitoring test per year and survey testing based on request. Protocol testing is designed to rigorously evaluate LDAQ solution performance. All testers who complete a program receive an independent report of results.

- During the expansion of capabilities effort, METEC will modify infrastructure to support hydrogen-natural gas blends. Initial focus will be on technologies that sense hydrogen and estimate hydrogen emissions. These technologies can be evaluated under the same programs (ad-hoc and protocol testing) as they are gas agnostic.

Building Data Sets to Improve LDAQ Analytics

The major shortfall in reducing uncertainty in emission quantification is a dearth of data. Even though methane is emitted at the METEC site 5 to 7 days a week, 50-weeks a year, publicly available methane concentration and matching meteorological/micrometeorological data are not generally available (Testers’ sensor reading at METEC belong to the solution developers as paying clients of the facility.) Large data sets are necessary to test and validate new approaches to emissions detection and quantification—a delicate balance between computational complexity, accuracy, and precision.

METEC 2.0 includes eight autonomous mobile methane measurement units (AMMMU) to collect this critical data. Each AMMMU will comprise multiple sensor types measuring methane concentrations in air with different technologies. Meteorological and micrometeorological data will be collected as well. AI engines will run QC/QA protocols on data in real time, which then will be livestreamed for instant access.

The first prototype AMMMU will be built and deployed at METEC during H1 ‘24. An additional seven AMMMUs will be constructed and deployed in the following six months. Following this, all eight AMMMUs will be deployed when the METEC team conducts testing—at METEC or remote sites.

To ensure data collected by the AMMMU network is useful to solution developers and operators, we will form an advisory board early in the design phase (January – February 2024) to identify key requirements for measurement and modelling. Contact Stuart Riddick (Stuart.Riddick@colostate.edu) for further information or to join the advisory board.

In addition to AMMMUs, the METEC facility at CSU will also host permanently-installed instruments that will produce a publicly-available data product.

Mobile METEC Capabilities

While the METEC facility emulates a few types of facilities, there is no way for one facility to emulate the breadth of complexity and environmental conditions seen in O&G facilities across the U.S. To address this issue, controlled testing will be expanded to include more complex facility types and meteorological conditions—METEC 2.0 will develop mobile release equipment to bring in-situ, blind testing capabilities to a wide variety of locations.

Mobile release rig capabilities have been proven on several field deployments to date. The longest continual deployment is currently active and has been running for 6 months. The current “rig” is solar powered, with remote control gas releases and data logging through the cloud and cellular data. Recently, METEC test rigs supplied process gas on an active midstream site to simulate seal vent emissions, and were coupled with a mobile CNG trailer to simulate wellhead emissions.

Building on these experiences, testing at both “mock” facilities without power or supply gas, and at operational facilities with utilities and gas supplies are both feasible. This flexibility will allow for solution testing using METEC-like testing protocols at any suitable location, allowing solution developers to test in complex wind fields created by large buildings, extreme terrain, snow cover, wooded surroundings, and other realistic conditions.

Two types of testing are possible:

- Controlled release testing—very similar to METEC—at locations where there are no active natural gas operations, such as a shut-in facility or non-gas facilities characteristics similar to gas facilities.

- Challenge release testing adds controlled ‘extra emissions’ to an operating natural gas facility to understand how leak detection and quantification solutions respond to the additional emissions.

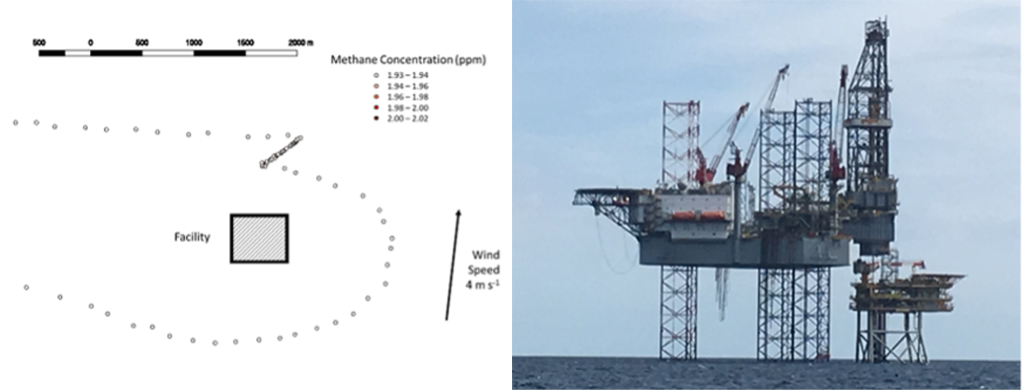

Testing Offshore

Recent studies have attempted to quantify methane emissions from offshore production facilities using methods developed and validated for quantifying emissions from onshore facilities, however, calculated emissions are much lower than expected, raising questions over the validity of assumptions made, including:

- Effects of the marine boundary layer as offshore wind fields differ substantially from onshore,

- Oceanic particulate affecting optic-based measurement systems,

- Offshore facilities’ emission plumes being too diffuse for current methods to detect,

- The reduction in light intensity as it reflects off the water’s surface, this may not be sufficient for many imaging solutions.

METEC 2.0 will investigate development of an offshore version of METEC to simulate behavior of emissions from offshore facilities. This capability would support a variety of testing protocols to independently validate current and developing quantification approaches. The main design features will include: gas release capability of between 5 and 500 kg methane per hour; release points that emulate both small leaks and large emissions commonly seen at offshore facilities, e.g. unlit flares and venting; meteorological, micrometeorological and environmental data collection; and gas storage with a remote-control release system will allow for autonomous, precision timed emissions.

Controlled testing cannot be performed on operational platforms where emission rates cannot be strictly controlled, and operational and safety concerns are prohibitive for the necessary large releases. The current plan is to use an abandoned offshore platform to provide a realistic yet simulated offshore controlled release test location. The size, type and location of the facility will be chosen after consultation with operators and solution providers but will be selected in terms of location (to provide ready access by drones and ships), size and structural features (representative of most common platforms), environmental conditions, and transferability to other operational areas (E.g., Nova Scotia, North Sea, west coast of Africa, Caribbean).

Developing this capability will be challenging. The METEC team will partner with offshore experts for design, construction, and operation of the facility. While the team has identified preliminary partners, we are still in the conceptualization phase, and input is welcome.

Engage: The project will include an advisory board to prioritize facility types, locations, and characteristics for controlled testing – and to help identify an existing facility. Advisory board input will drive choice of location, testing capabilities, and testing plans. We encourage active participation to ensure this facility meets your requirements. Contact Stuart Riddick (Stuart.Riddick@colostate.edu) for further information or to join the advisory board.

Testing Satellites

Methane satellites are progressing rapidly. These satellites range from wide-area instruments that observe regions with large pixels (e.g. TROPOMI instrument on Sentinel 5) to tasked satellites that can focus on facility-scale infrastructure or narrow strips at much higher resolution (e.g. satellites from GHGSat™, CarbonMapper™, and MethaneSAT™).

Characterizing the performance of these systems is challenging. Since each satellite passes over a given location only once in several days given orbital dynamics and cloud cover, a single testing program may take months to acquire the hundreds of data points needed to characterize a solution.

METEC 2.0 will develop a test location that can remain in operation for 9+ months, with the continuous gas supply required for long-duration testing programs. The METEC team is exploring midstream locations which have sufficient gas supply for testing and are suitable for the remote control required for months of testing. Release capabilities will be designed to be moved occasionally to new locations.

Test protocols, release capabilities, and test programs will be designed in conjunction with host facilities, satellite developers, and a broad stakeholder group. Contact Ezra Levin (Ezra.Levin@colostate.edu) to be included in the design discussions.

METEC Research Group – Field Campaigns

The METEC Research Group has a long history of directly measuring emissions at O&G facilities—and a few other locations—during extensive field measurement campaigns, frequently engaging in three types of campaigns.

-

Large national campaigns that characterize emissions in one sector and a specific type of facility. Examples include emissions from marginal wells and landfill natural gas plants, gathering compressor stations and transmission and storage sectors.

- Intensive regional campaigns to compare multiple methods and characterize emissions from a basin or political jurisdiction. Completed projects include the Colorado Coordinated Campaign (C3) and the Fayetteville Study. Ongoing projects include SABER (Site-Aerial-Basin Emissions Reconciliation), a bottom-up, top-down reconciliation project in both the Denver-Julesburg and Upper Green River basins. And COBE (Colorado Ongoing Basin Emissions), which will fly multiple aircraft detection solutions in all major gas-producing basins of Colorado. These measurements will be combined with statistical modeling to produce emissions estimates for each basin that will be compared to state GHG reporting from operators. Both SABER and COBE involve significant operator participation to provide additional measurements (SABER only) and insight on causes of emissions.

- Specialized informational studies conducted directly with industry. For example, a recent study characterized compressor emissions on production sites, assessed a measurement informed inventories at midstream facilities, and assessed leak detection and repair processes with distribution operators.

The METEC Research Group typically engages in complex field campaigns in direct cooperation with operators. Our hybrid measurement capability is especially suited to unusual or complex sources that require new method development and/or require multiple capabilities simultaneously.

METEC operates a mobile laboratory with a suite of instrumentation that can measure emissions from a variety of sources, using a variety of techniques. Emission rates of numerous species from stationary combustion sources can be quantified using customized methods and instrumentation (FTIR). A separate system measures atmospheric trace gases (CO2, CH4, C2H2, C2H6, H2O, N2O, NH3, etc.) using a variety of instruments. These measurements are coupled with supporting MET data to produce emission rates using standardized methods including OTM33, and dual tracer flux. Common LDAQ approaches including OGI and Hi-Flow sampling are also possible.

METEC researchers often coordinate multiple measurement teams on a project by developing the sampling plan and coordinating the program, rather than doing all the measurements ourselves. Recent and ongoing projects coordinated work by multiple universities and/or industrial measurement teams.

METEC, EEMDL, and MAES: A Foundational Approach to Emissions Modeling

Emissions modeling fills gaps between measurement campaigns and a full understanding of emissions. For example, if measurements were taken at a small number of facilities, emissions modeling can be used to scale those measurements spatially and temporally to an entire basin or region. Emissions modeling underlies all differentiated gas efforts, as it’s impractical to measure every step, at all times, of a differentiated gas supply chain. Robust emissions modeling includes uncertainty models for measurement methods (e.g. aircraft, continuous monitoring systems) and for scaling assumptions (spatial and temporal); this is a topic for active research.

METEC’s modeling effort is centered on Mechanistic Air Emissions Simulator (MAES) emissions model for oil and gas facilities, augmented by custom models as needed. Mechanistic modeling in MAES couples a physical understanding of fluid flows (how, when, and at what rate fluids flow through equipment) to where, how often, and how long failure modes (e.g. leaks) occur. MAES’ mechanistic modeling contrasts with traditional emission factors modeling, where each piece of equipment is assigned a set emissions factors that do not scale with fluid flows or change with equipment state or interconnections. MAES simulates a wide-variety of gas species in addition to CH4, and simulates how gas composition varies across facilities—something traditional models do not include.

Current modeling uses prototypical sites—example facilities developed in conjunction with operators—to simplify modeling.

MAES is available as a service for groups interested in a more realistic and flexible emissions modeling approach than emission factors modeling. Please contact Jerry Duggan (Jerry.Duggan@colostate.edu).

Emissions modeling takes … well … a village. With that in mind, the METEC group is part of the Energy Emissions Modeling and Data Lab (EEMDL), and industry-funded consortium including the University of Texas at Austin, CSU, and Colorado School of Mines. EEMDL’s mission is to provide reliable, science-based, transparent, and measurement-based greenhouse gas emissions assessments of global oil and gas supply chains. The group is using three key approaches: developing community models and tools for greenhouse gas emissions assessments, making publicly available timely, high-resolution emissions datasets, and creating educational and training materials to enable widespread use of EEMDL’s models and data.

Opportunities to Participate:

Interested in participating? There are several ways to get engaged in this project, please contact kate.laughery@colostate.edu for further information.